Cause 1: Impurities in the filament or mismatch between the model printing temperature and filament temperature

Solution:

Cause 2: Carbonized filament buildup on the nozzle

Issue: During manual filament feeding, the extruded filament diameter is less than 0.45mm. The normal diameter shall be around 0.5±0.03mm.

Solution: Replace the nozzle.

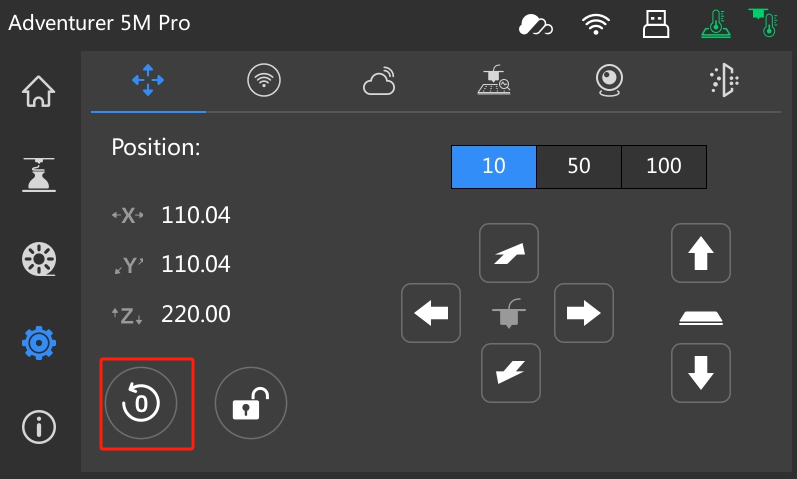

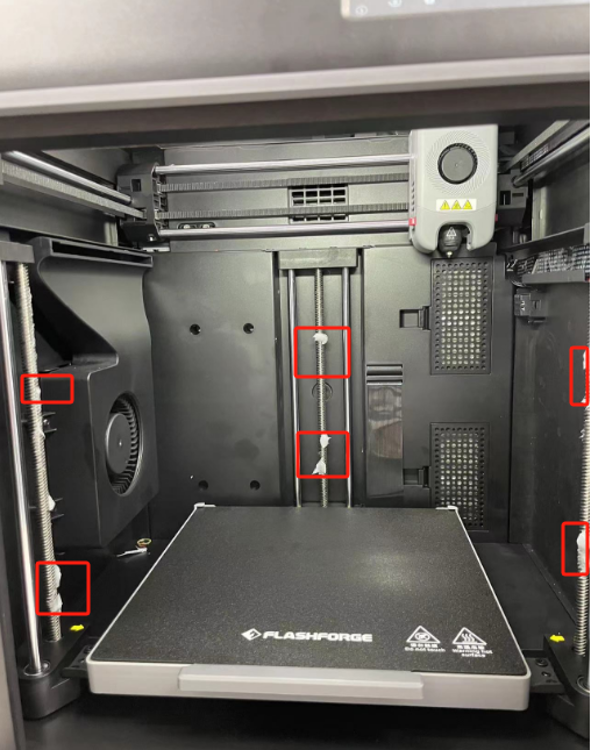

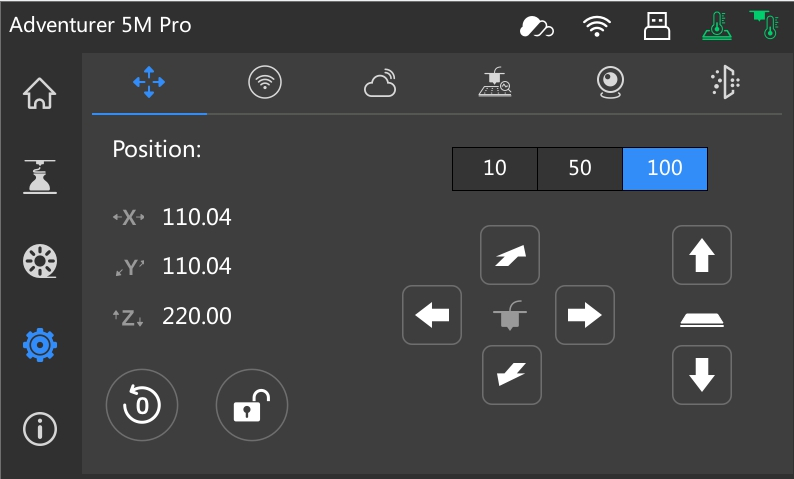

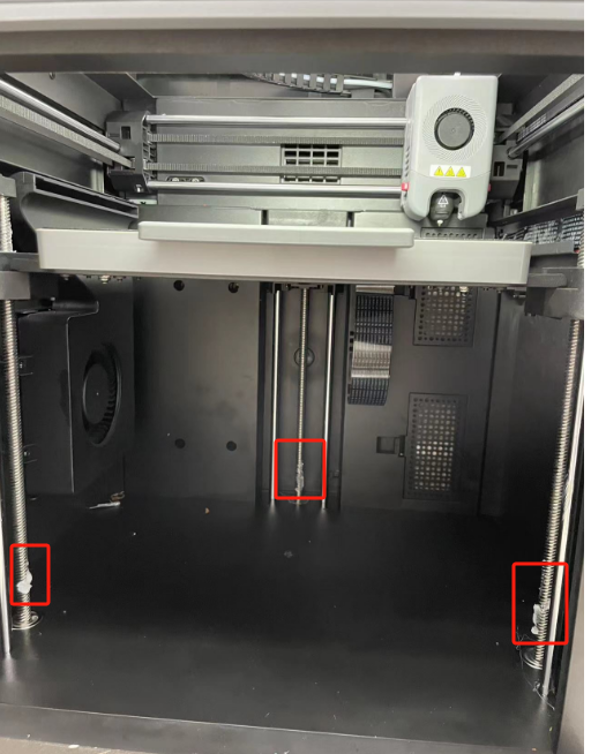

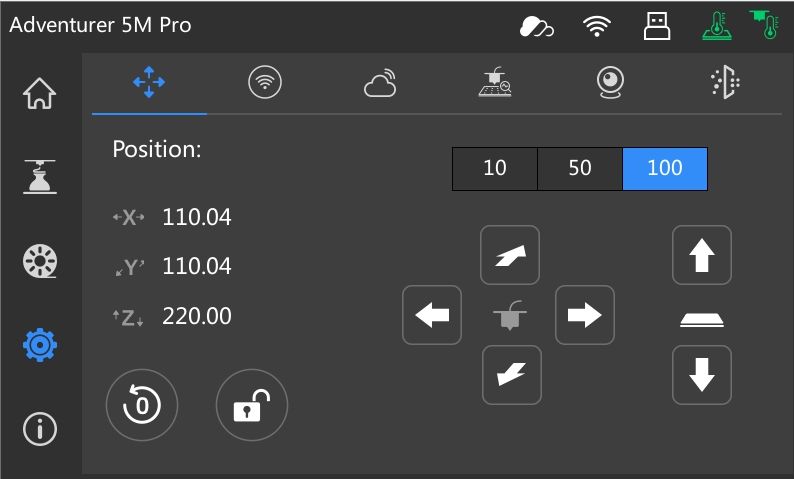

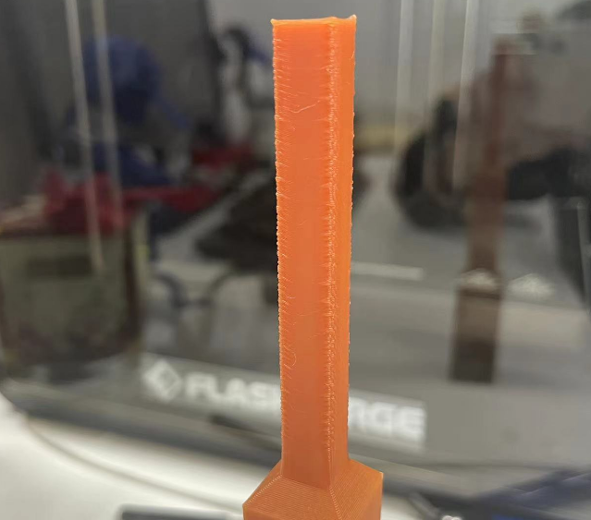

Cause 1: Z-axis movement is not smooth.

Issue: Abnormal noise or jamming during Z-axis up-and-down movement.

Solution: Apply grease to the Z-axis lead screw.

Cause1: Insufficient belt tension

Solution 1:

Solution 2:

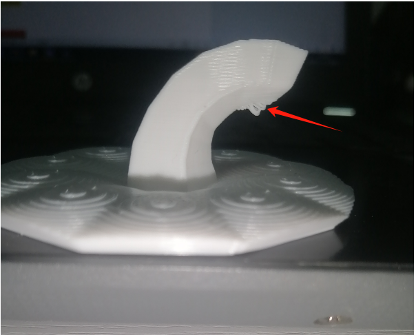

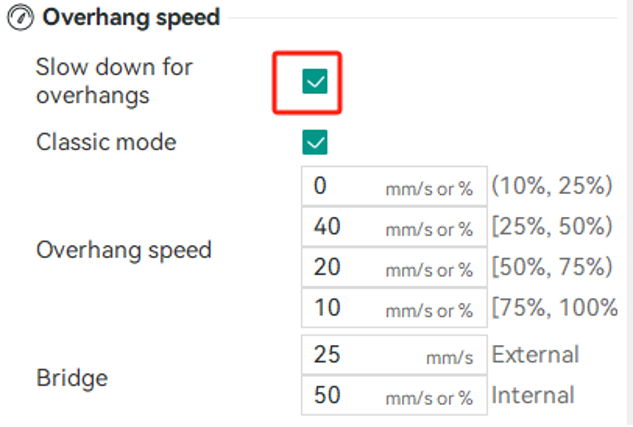

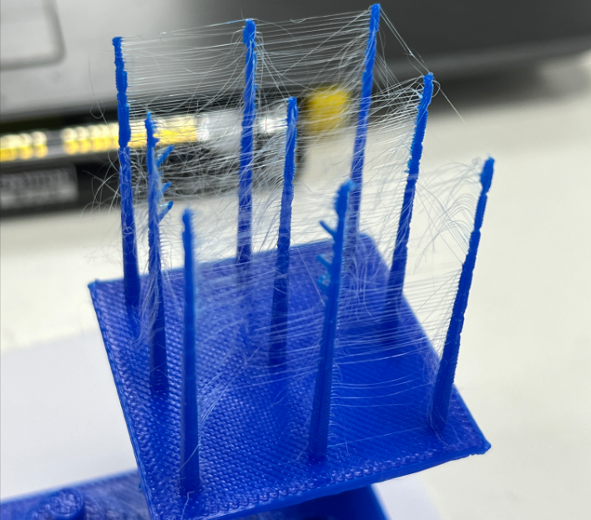

Cause 1: Overhangs at large angles

Solution 1: Enable “Slow down for overhangs” in OrcaSlicer.

Solution 2: Add supports for overhangs at an angle greater than 30°.

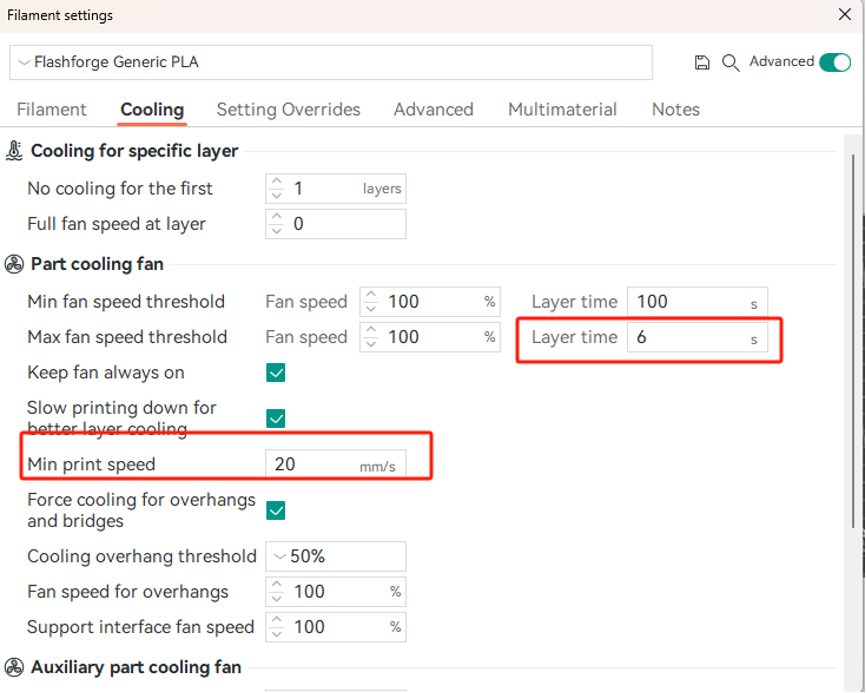

Solution 3: Increase the cooling fan layer time and reduce the minimum print speed in OrcaSlicer.

Cause 2: Malfunctioning cooling fan and auxiliary fan

Solution: Please refer to the video for instructions on [replacing the cooling fan and turbo fan](/en/adventurer-series/maintenance/ad5mseries-replace-the-turbo-fan-and-cooling-fan =650x).

Cause 1: Filament that has absorbed moisture can become brittle and prone to breaking (especially for PLA, PETG, and ABS).

Solution : Dry or replace it with a newly unpacked filament.

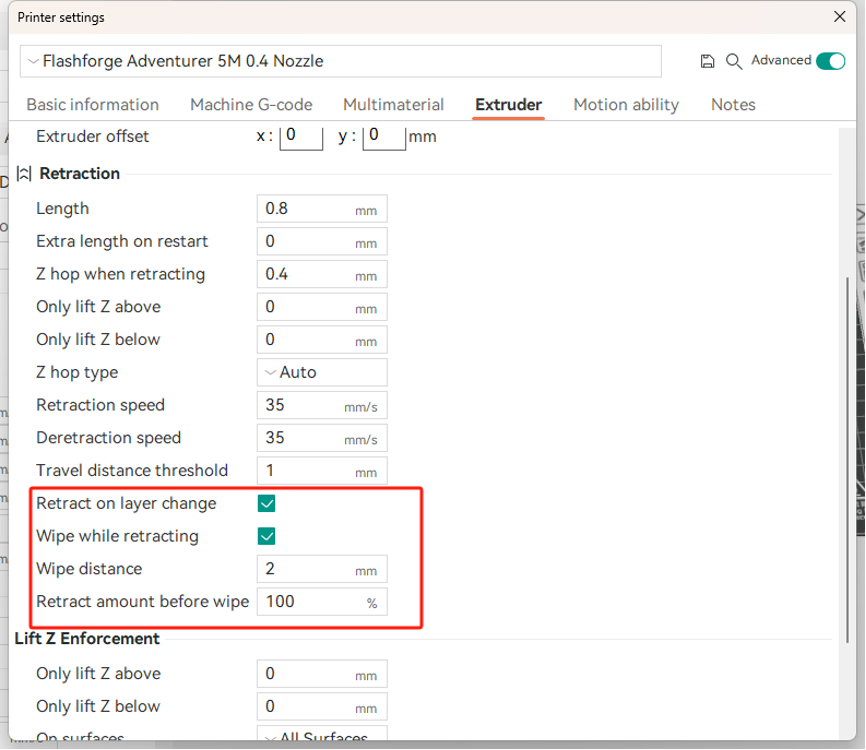

Cause 2: Insufficient retraction

Solution: Use OrcaSlicer to increase the retraction amount and retraction speed appropriately, and enable “Retract on layer change” and “Wipe while retracting”.

Cause 3: Incorrect temperature setting

Solution: Adjust the extruder temperature.

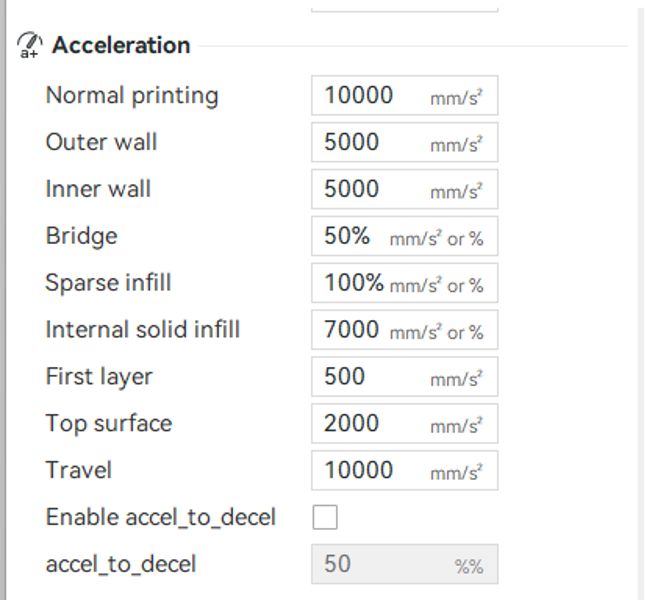

Cause: Model printing speed too fast, insufficient cooling

Solution 1: Reduce the print speed in the slicer.

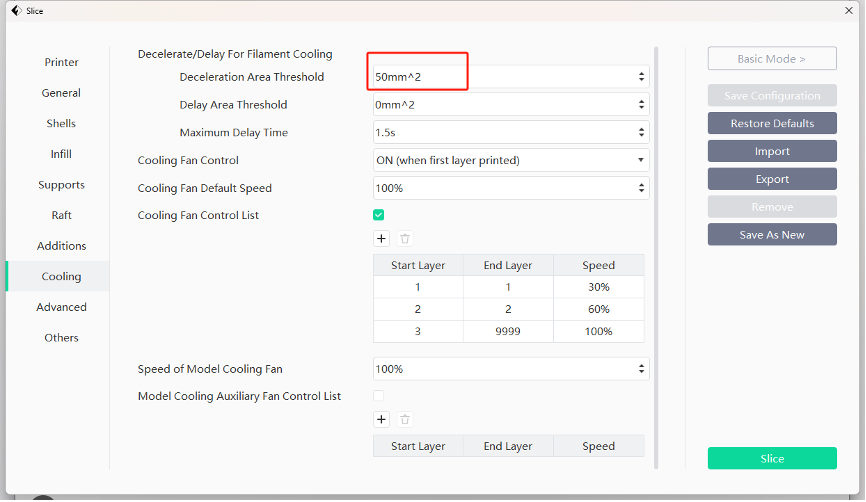

Solution 2: Adjust the “Deceleration Area Threshold” in the slicer to make the printer automatically slow down for smaller areas of the model.

Updated on 31 Aug 2024